Eduardo Cervantes López, international consultant: Management and Innovator in poultry processing, was in charge of the conference on "Decalogue of Quality and Yield: From the farm to the processing" during the LPN 2021.

After the broilers receive the best possible care during growth and are ready for processing, reaching the largest number of birds or kilos per square meter, the pre-processing stage begins PRESLAUGHTER. It is a new experience for them, who have been conditioned to a quiet environment and with the least degree of disturbance when the personnel who attend to them enter the poultry house.

Broilers are fattened in poultry houses with and without compartments. When the birds are to be grouped in the latter, the catching crew personnel generally enter in pairs holding railings or stretches of canvas, walking hurriedly, and making noise to move the flock and define the group. The instinctive reaction is immediate, beginning to run, flapping intensely, initiating short flights with the purpose of staying on the backs of its fellows, holding on with its nails to avoid falling.

Everything is CHAOS!!

Consequences: Wings battered to varying degrees, scratches on the back, great stress, etc.

Once locked up, another traumatic stage begins Collection. Two methods are traditionally used:

By the legs and taking them by the body, keeping the wings attached to it without squeezing the abdomen, which would cause them difficulty breathing.

The capture by the legs walking with them to where the cages are is very fast and economical when using crews of 6 to 10 people depending.

However, the consequences are evident:

- Bruises where the thigh articulates with the leg if they hold it incorrectly.

- Flapping with different intensity levels produces bruises on both sides of the wings.

- Dislocations of the femoral head result from turning the femur 180 degrees while skinning the worker. Bleeding occurs.

- Bleeding in the breast due to rupture of blood vessels due to the great pressure received when the wings lower.

- Fractures of the thoracic bones. They are the most fragile.

Trapping by carcass when all conditions for keeping animals still are met has shown an average reduction of 50% in seizures.

However, in some poultry houses, the following situations that increase the Losses of Salable Products are detected as normal practice:

- Lots of light: Chickens are in a state of high alert.

- Excessive noise: They use forklifts that run on DIESEL fuel. These teams create stress for them. Blood pumping to the wings and thighs is increased. They are ready to run.

CAGES WITHOUT LIDS

The birds do not put them inside the cages but throw them around like basketballs. Many of them bang their wings, and their backs bump into the perimeter where the lid is put on. So, the million-dollar question arises: Is it possible to decrease the flapping of birds when they are picked up by the feet? Etc. Answer: Indeed! This objective is fulfilled if a small detail is taken into account while handling the chickens.

Dear reader, during the presentation, you will watch the videos confirming how the damage to the integrity of the animals is LOWERED. For this reason, I invite you to put it into practice. If, in your company, you decide to catch the chickens by the legs with this implementation instead of holding them by the body, the current costs of this operation will be reduced.

CAGE SIZES

Usually, three sizes of birds are sent to the plant: Small - Roasters-, Medium, and Large, which are transported in cages that have the same internal height.

For some time, it has been found that plants process a GIANT size to meet the growing demand of a market that grows daily. Despite this reality, many processors continue to use the same cages. They only reduce the number of birds so that they are comfortable during the trip to the plant.

A new reality has been found: the animals get up during the journey, and if the road is not in good condition or there are speed bumps, the chickens suffer blows that turn into BRUISES on their backs. This detail affects the final quality of the processed pole: Grade A.

DROWNED CHICKENS

They represent a TOTAL Loss!!

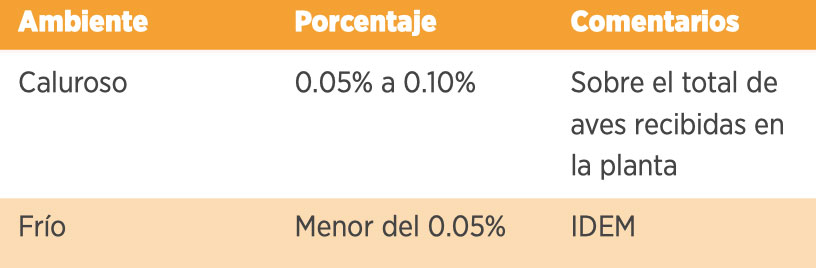

Many companies use specially equipped trucks to transport birds in both hot and cold climates, achieving these loss percentages:

PROCESSING

During slaughter at the processing plant, quality deterioration is caused to the birds by inadequate work methods, mismatched equipment, incomplete infrastructure, etc.

HANGED ON SLAUGHTER AIR CONVEYOR

Some operators hold the chickens by the area where the thigh articulates with the leg, keeping it tight. This inadequate handling causes BRUISES, which can be seen as reddened areas. They can be discarded as Grade A quality birds depending on the severity.

- Recommendation: Hold the animals forming a 90-degree angle between the thighs and the legs. In this way, the pressure the legs receives does not cause any deterioration.

BREAST MASSAGER

This implementation must be well-graded and rigidly supported. Additionally, the hanging section must be darkened and illuminated with special blue, red, or green lights. As far as possible, this path to the stunner should have as few curves as possible.

Remember that these changes in rotation alter the tranquility with which the birds move, a condition that not favors a good stun. If all this physical and operational infrastructure scenario is adjusted correctly, the chickens SHOULD NOT FLAP. In the previous stage, the negative consequences on quality were explained.

It is worth noting that the time between the last hanger and the stun should be in the following range: 20 to 30 seconds to decrease blood pooling due to gravity. Likewise, flapping contributes to increasing the amount of blood lodged in the blood vessels of the wings. This reaction by broilers increases blood pumping to prevent muscles from cramping. Depending on the volume of blood deposited, it is not enough to evacuate, noticing the blood vessels full of blood at the exit of the last plucker.

STUNNED

Broilers should enter the vat of this equipment similar to the scalder. When this condition IS NOT MET, the animals touch the wet ramp with energized water with their wings and breast.

Already warned, many of them do not put their heads in the tub. But, when they do, a chain reaction occurs:

- They raise their neck above the water and keep it in that position until they get out of the tub.

- They flutter intensely, hitting their wings with their neighbors and the cabinet: BRUISES.

- They rise supported on the hooks and are dropped vertically. Effect: Dislocation of the shoulder joint: clavicle and humerus. At the exit of the plucker, a BLEEDING is noticed around this area.

Recommendation: Installing a section of tube or metal rod separated approximately 1 inch over the vent area and the lower part of the breast will prevent it from rising, making it easier to introduce the head into the water, leaving you unconscious immediately.

- When the variables: Frequency, Voltage, and Amperage are not well graduated according to the range of weight of the birds and sex, etc., they suffer excess current that increases muscle contraction, affecting the quality of the plucking. Remember that the time spent in the vat ranges from 10 to 12 seconds. Similarly, blood spread is created on the breast, wingtip, and tail.

SCALDED AND PLUCKED

All the variables that control these two operations must remain stable to achieve productive plucking: Less damage to the skin of the birds.

SCALDING

- Temperature: With the minimum possible variation.

- Water level: Cover the bottom of the hooks

- Turbulence: Be uniform throughout the tank

- Time: According to the type of broilers being processed. Yellow with epidermis. White without it.

They must be permanently closed. Those that recirculate the water in a cascade are excepted.

The path between the exit of the scalder and the entrance to the first plucker must be covered in order to conserve heat.

PLUCKED

- Use lukewarm water: 34°C to 38°C to maintain the heat that the broilers gained from scalding.

- Rubber fingers should be placed on the disc lines with an adequate hardness to remove feathers on different parts of the birds. The skin has various characteristics. In addition, some feathers are inserted in the muscles: Those of the tail and the wings.

- When you have several pluckers, the percentage of feather removal must be distributed in such a way that the first machine removes about 75%. The second, 20%, and the last, 5%. In this way, the pressure of the fingers is better distributed in order to reduce friction on the skin of the chickens.

- Every day at the end of the process, the state of the fingers should be checked, replacing those that are:

- Worn

- Splits

- Falls

If this control practice is developed in a disciplined manner, the following benefits are achieved:

- Decreased skin damage corresponding to the breast area and upper part of the thighs.

- Reduction of Dislocations in the wings: "Pop-out."

- The monthly consumption of fingers will be less than or equal to the International parameter: 1 finger for every 2,000 chickens processed.

- Example:

- Monthly process: 1,000,000 birds

- Change month: 500 fingers.

- Example:

In summary, the current levels of seizures detected in the processing plants I have reported range between 0.5% and 2.0%. They can be SIGNIFICANTLY DECREASED if the details above are monitored in real-time to take corrective actions in the shortest possible time.

Barranquilla, Colombia, September 15, 2021